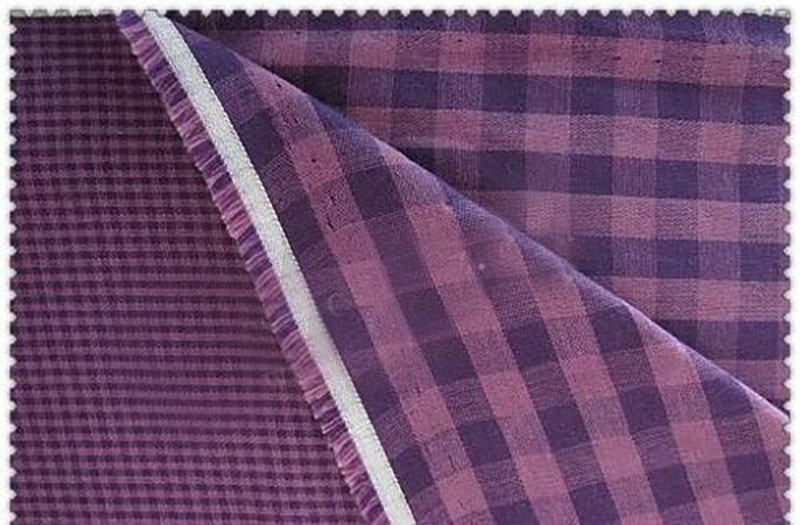

Double Layer Cloth Yarn Dyed

Double Layer Cloth yarn dyed is an overlapping fabric formed by interweaving two or more groups of independent warp yarns with two or more groups of independent weft yarns, collectively referred to as Double Layer Cloth yarn dyed. Then in the Double Layer Cloth yarn dyed-layer fabric, the warp and weft of the upper layer are called table warp and table weft, and the fabric formed by the interweaving of table warp and table weft is called the surface fabric. The lower warp and weft are called the inner warp and inner weft. The fabric formed by the interweaving of the inner warp and inner weft is called the inner fabric, and the interweaving points of the warp and weft connecting the upper and lower layers of the fabric are called junction points.

Product Features

From the characteristics of Double Layer Cloth yarn dyed-layer fabric, that is, two pieces of fabric are directly organized together through technical means, and two pieces of fabric can be directly separated or connected together. Simply put, you can use fabric on both sides, or you can use one side.

That is, the fabric it can make is very soft, very light, breathable, suitable for shirts, shirts, etc., or conventional clothing fabric; It can also be used as a very thick, more elegant, finished products can be used as clothing fabric or more fashionable special fabric.

Double Layer Cloth yarn dyed layer cloth can also be divided into a variety of different textile raw materials: cotton Double Layer Cloth yarn dyed layer cloth, polyester cotton Double Layer Cloth yarn dyed layer cloth, elastic Double Layer Cloth yarn dyed layer cloth, human cotton Double Layer Cloth yarn dyed layer cloth, cotton brocade Double Layer Cloth yarn dyed layer cloth and other kinds of Double Layer Cloth yarn dyed layer cloth.

In fact, Double Layer Cloth yarn dyed can be plain weave both front and back, it can also be the front is twill and then the back is plain weave organization, and it can be the front is jacquard organization and the back is twill or plain or jacquard organization.

In addition, different raw materials, colors, yarn branches, organization, and other technologies are used in the early weaving process of Double Layer Cloth yarn dyed-layer cloth, so that the cloth produced will wrinkle and blister in the later dyeing process. You can also do all the dyeing and finishing processes on this cloth, including: antibacterial and deodorizing, crepe pressing, printing, pressing, coating, and so on.

Application and After-Sales Service

From the characteristics of Double Layer Cloth yarn-dyed cloth, that is, two pieces of fabric woven together directly, two pieces of fabric can be separated, can also be connected together.

The characteristics of Double Layer Cloth yarn dyed cloth: are that can be made very soft, light, and breathable, used for shirts, shirts, etc., or conventional; It can also be made very thick and elegant, as a special fabric of clothing or fashion.

A thick fabric of cotton or linen, named for its original use in sails. Generally, plain weave is used, and a few varieties are twill weave. The warp and weft yarns are used with multiple strands. Rough canvas, also known as canopy cover cloth, commonly used 58 (10 British branches)4 ~ 7 strands of thread woven, fabric strong resistance to twists and turns, has good waterproof performance, is used for transport cars, open warehouse cover cloth and field tent cloth. Thin canvas warp and weft yarns are generally 2 strands No. 58 ~ 6 strands No. 28 (10 British /2 ~ 21 British /6), used for labor protection clothing and supplies. After dyeing, it is also used as shoe fabric, travel bag, backpack, and canvas suitcase material. Some of the fine canvas used for shoe making can be woven into a Double Layer Cloth yarn-dyed layer of tissue, combining the upper and the inside of the shoe as a whole, which can improve the quality of the upper. In addition, there are rubber canvas, heat, fire, radiation shielding canvas, paper machines with canvas, etc. Rubber canvas requires high strength in the warp and weft direction, uniform warp and weft density, a small gap difference between the warp and weft lines, and no oil pollution, which is conducive to uniform infiltration of rubber liquid. The canvas for paper-making machines requires a thick cloth body, suitable for soft and hard, clean and flat cloth surfaces, and good moisture permeability. The raw materials of the canvas have been developed into chemical fiber and glass fiber so that the canvas has better performance.